LED Theory and Ruggedization

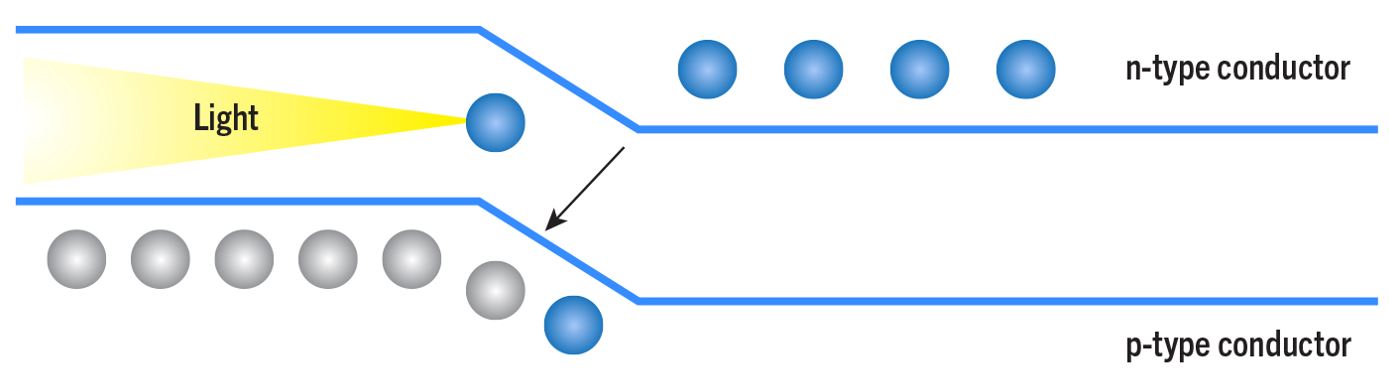

Light emitting diodes or LEDs comprise special semiconductors, both rich and deficient in valence electron density. At the junction of the two semiconductors (n and p-type semiconductors), electrons from the n-type conductor migrate to holes in the p-type conductor. This transition gives off a photon of light with much less energy wasted as heat when compared to incandescent bulbs.

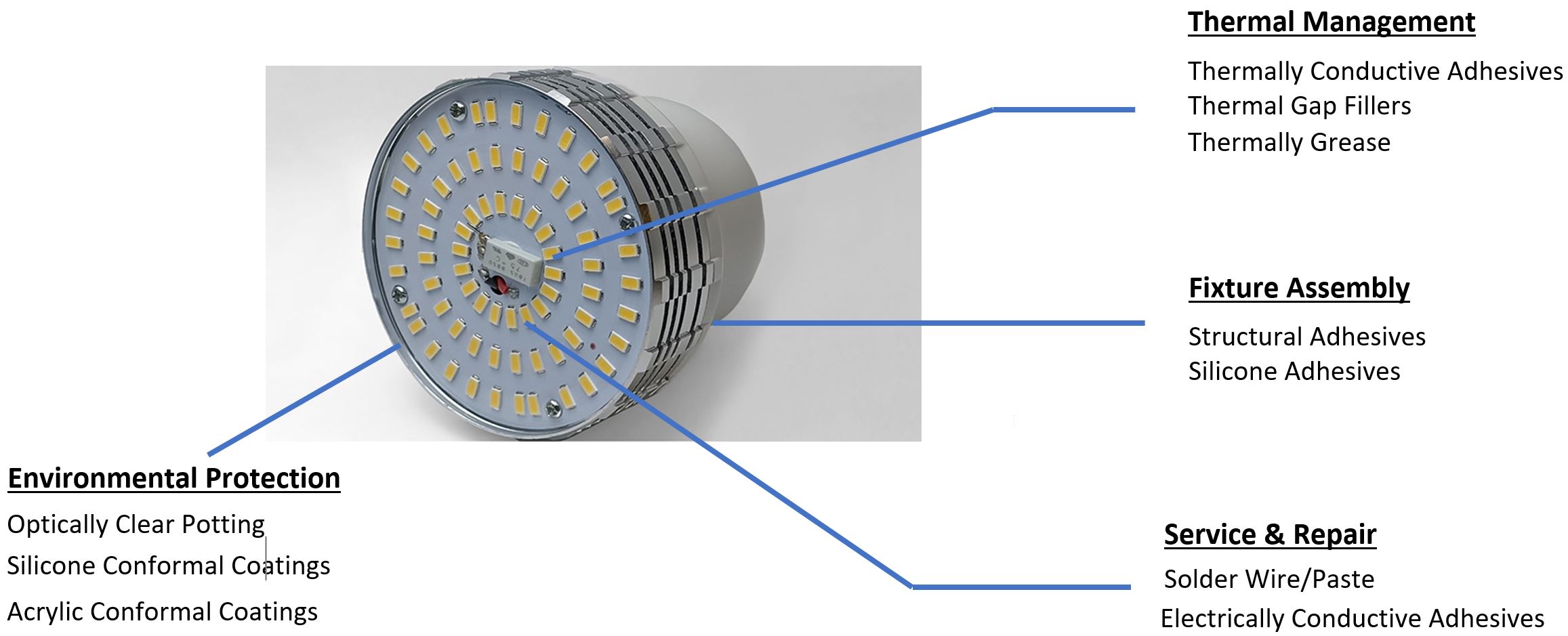

The popularity of LEDs stems from their superior efficiency compared to incandescent bulbs, which translate into a lower operating cost and longer lifespan. It is important to invest in products that will help extend the lifespan of LEDs, especially in harsh environments where specialty coatings, resins and adhesives are needed to protect these delicate electronics from stresses such as mechanical impacts, precipitation, sunlight, and potential exposure to harsh chemicals. MG Chemicals offer a full line of products suited for the LED industry, such as protective coatings, potting and encapsulating compounds, thermal interface materials (TIMs), structural and specialty adhesives.

Protection from the Environmental impacts

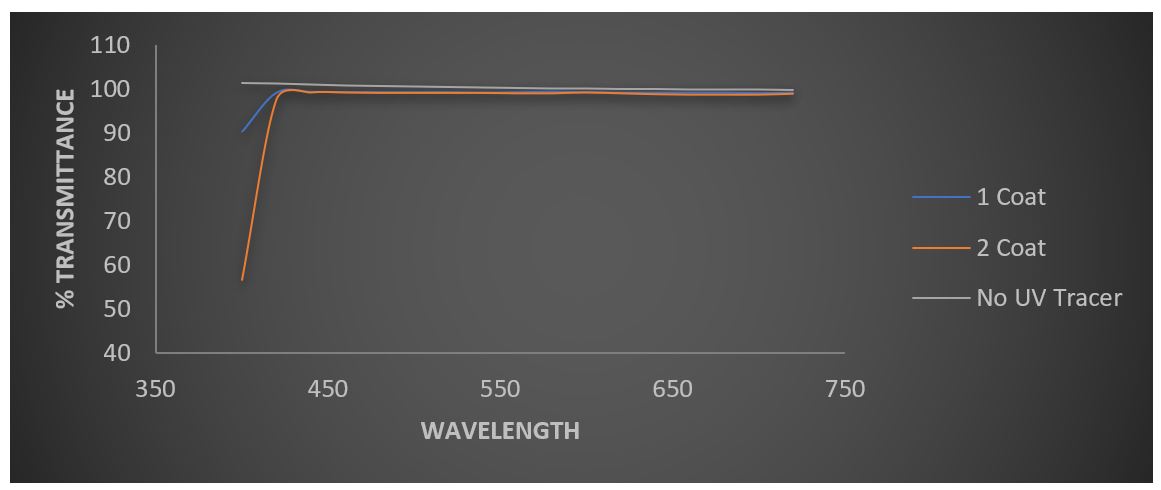

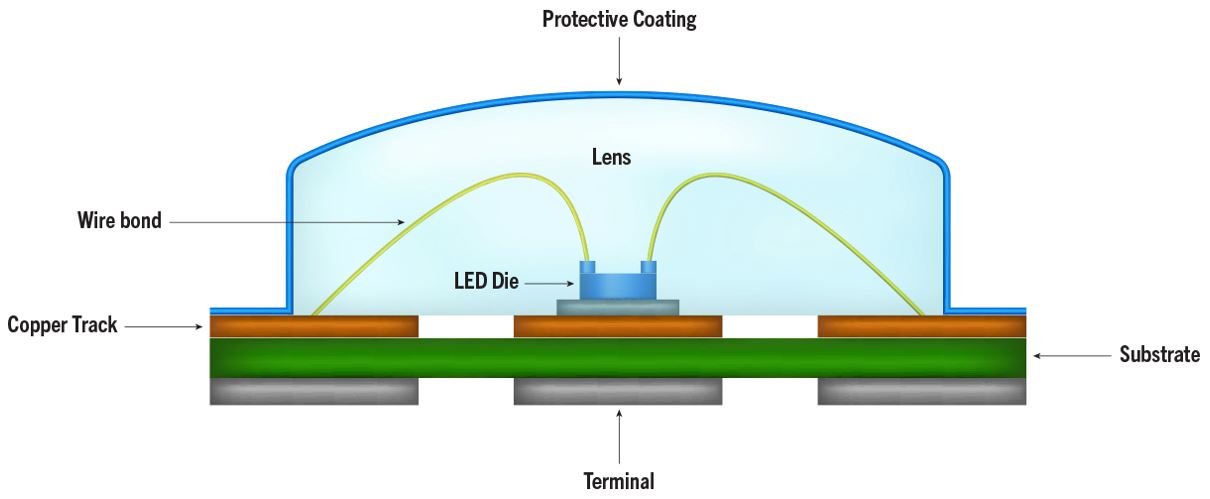

Many LED fixtures are used in outdoor applications such as residential lights, commercial flood lights and signage and therefore require protection from environmental stresses. Precipitation, mechanical shocks, extreme temperatures, high humidity, and exposure to chemicals can all negatively impact LEDs causing corrosion, compromised light output, and structural failure. MG Chemicals’ portfolio of conformal coatings and potting compounds offers products that can be applied over the LED lens providing a protective barrier. Specifically, acrylic and silicone conformal coatings prevent moisture ingress, fungal decay and erosion from airborne dust and other foreign particles. Special consideration must be taken when using a conformal coating as these products contain UV tracers that aid in coverage inspection; however, these dyes also absorb strongly below 440nm, so LEDs with output in this range would need special consideration; namely conformal coatings without a UV tracer.

For protection against chemical exposure or physical shock, LEDs can be encapsulated with protective resins such as our 832WC or RTV615, which dampen shock and protects against photo-oxidation, thus ensuring the fidelity of light output to diverse elements.

Thermal Management

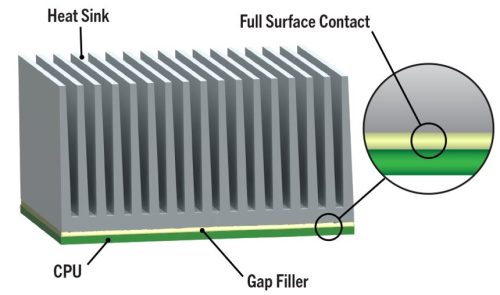

The longevity of an LED depends heavily on the efficiency of heat dissipation. While LEDs produce far more light per Watt used compared to incandescent bulbs, they still expend a lot of energy as heat, making thermal management a critical control factor. Heat dissipation is achieved by different mechanisms requiring different solutions accordingly. Heat from power components on the LED driver can be controlled using low viscosity, thermally conductive resins like our 834B, 834HTC and 832TC. Thermal adhesives, thermal pastes and gap fillers are used to displace air at the component/heatsink interface to prevent overheating. MG Chemicals offers thermal interface materials (TIMs) in many consistencies, from flowable liquids for bonding horizontal surfaces to thixotropic pastes. These products are specially formulated to control bond line thickness helping achieve maximum heat flow through the interface.

Fixture Assembly

The benefits of LEDs, including their long lifespan, high energy efficiency, and ability to operate in colder temperatures, make them versatile lighting sources. New LED fixtures have emerged for indoor and outdoor applications with an increasingly creative design that requires the pre-fabrication of different parts assembled with structural adhesives. MG Chemicals offers a wide range of structural adhesives, from rigid epoxy systems with a superior bond strength to low modulus silicone adhesives for bonds that require flexibility. Our adhesives bond to various plastics, metals, glass, ceramics, and wood. There are also specialized adhesives such as electrically conductive, thermally conductive, and flame retardant depending on your requirements.

Service and Repair

To assemble or repair an LED circuit board, periodic removal and replacement of circuit components may become necessary. Conventionally, this is done through soldering; however, electrically conductive adhesives can also be used when the high temperatures of soldering are forbidden. MG Chemicals’ solder line includes everything you need to solder from, whether you’re a hobbyist or a large industrial producer. We also carry strong electrically conductive adhesives that can be used for cold soldering, localized trace repair or stencilling.

Summary of Solutions