As PCB designs become more miniaturized, and with the propagation of wireless devices, designers face new challenges in dealing with the problem of electromagnetic and radio frequency interference (EMI/RFI). The problems of EMI/RFI vary in scale, ranging from individual components and PCB board to entire rooms and buildings which need to be addressed by designers when considering which solution is most practical. You can read more about EMI / RFI shielding solutions here.

Shielding small ICs at the chip level is very different from shielding a room, so a clear understanding of the problem’s scale is essential (MacArthur, 2020).

Breakdown of EMI Shielding Levels

- Packaging level

- Board level

- Device and room level

EMI/RFI problems are best dealt with at the source. However, when this is insufficient, shielding must be scaled to ensure adequate protection.

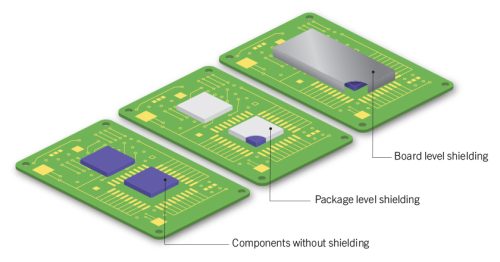

Package Level Shielding

The most fundamental level of EMI shielding lies at the individual package level. The approach here is to fully shield individual components (packages) from transmitting harmful electromagnetic fields that interfere with neighbouring components, disrupting the function of their circuits. The classic approach to remedy these problems was to surround the component with an electrically conductive shield, such as an aluminum enclosure. This was called metal stamping or canning. While effective, it was quite cumbersome, and added unnecessary weight to the component.

The most fundamental level of EMI shielding lies at the individual package level. The approach here is to fully shield individual components (packages) from transmitting harmful electromagnetic fields that interfere with neighbouring components, disrupting the function of their circuits. The classic approach to remedy these problems was to surround the component with an electrically conductive shield, such as an aluminum enclosure. This was called metal stamping or canning. While effective, it was quite cumbersome, and added unnecessary weight to the component.

Electrically conductive paint provides distinct advantages for package level shielding, including reduced weight, cost, and labor. MG Chemicals has developed specialized conductive paints that are specifically designed for package-level use. These paints can easily be applied directly onto the component, providing an effective EMI shield with the following advantages:

- Can be applied ultra-thin (down to 8 µm)

- Offers excellent flexibility, toughness and adhesion

- Stable under extreme environmental conditions

- Withstands wave soldering

Board Level Shielding

The next level up from package level shielding is board level shielding. With this approach, the whole board, or a portion of it, is surrounded by a six-sided metallic enclosure, which not only contains the EMI being transmitted from the device but also prevents neighboring EMI from interfering with the circuit. As with metal stamping, this solution was expensive and added unnecessary weight, so designers switched to using cheaper plastic housing materials, such as ABS spray-coated with conductive paint.

MG Chemicals has created an extensive portfolio of conductive paints for board level shielding with different chemistries and levels of shielding effectiveness. Our board level paints present a practical solution for reducing EMI, as they are light weight, cost-effective, easy to apply, and provide strong adhesion to most plastics.

Device and Room Level Shielding

Sometimes it is best to simply shield the entire device for added protection – for example, car batteries in electric vehicles. As with board-level shielding, device-level shielding is achieved by placing the device in an enclosure and applying an electrically conductive paint to all sides, which prevents unwanted EMI from leaking out or getting into the device.

EMI protection can also be extended to entire rooms, such as server rooms, surgical rooms, and airplane cockpits. Our water-based conductive paints are ideal for room-level shielding as they have low odor, low VOC, and adhere to drywall without a primer.

References

MacArthur, D. (2020, January 7). Let’s talk about shielding at the PCB level. In Compliance Magazine, from https://incompliancemag.com/article/lets-talk-about-shielding-at-the-pcb-level/.

Pingback: Soluciones de MG Chemicals para la industria automotriz – Adhesivos Industriales | Uniones Adhesivas México