Understanding The UL 746E Standard

Background

Underwriter’s Laboratories (UL) is a global safety certification company that performs testing on products across many industries and certifies them as fit-for-use. It is very common to see the UL label on consumer goods throughout the world, and this extends to protective coatings for circuit boards. The UL746E Standard comprises a series of tests meant to evaluate whether a conformal coating can withstand sudden electrical surges and maintain its dielectric integrity. The Standard contains three coating designations. Conformal coating is the most difficult designation to achieve and comprises both dielectric and fire retardance testing. Permanent and resist coatings are the other two designations, which constitute only testing for flame retardancy.

Testing Specifics

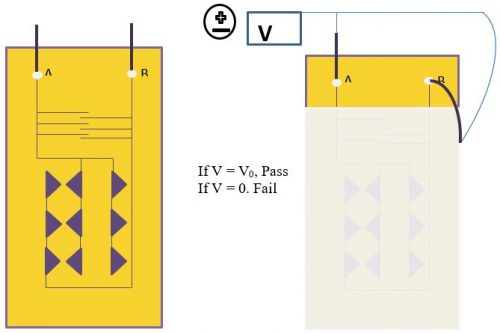

For designation as a conformal coating under the 746E standard, coatings must comply with stringent requirements comprising both dielectric and flame retardance testing. For the dielectric testing component, a trace pattern is coated with leads attached. Conductive foil is then placed over the sample and the test vehicle is subjected to a series of high voltage blasts. If voltage is maintained between the electrical leads of the test vehicle the coating insulation is sufficient; however, if the coating is unable to withstand the surge and breaks down, the circuit shorts, and amperage leaks to the conductive foil. Figure 1 (below) illustrates the concept behind the dielectric testing component of UL746E.

Table below lists the specific tests for UL746E Conformal Coating Designation.

| Test | Test Description |

| As Received Voltage Transient | sample pulsed with 6kV |

| Environmental Conditioning | Sample exposed to high humidity and then ambient, pulsed with 6kV |

| Humidity Conditioning | Sample exposed to high humidity and immediately pulsed with 6kV |

| Thermal Conditioning | Sample aged for several weeks in thermal chamber, pulsed with 6kV |

| Vertical Burn Test | Burn rate of vertically mounted sample measured for compliance |

For permanent and resist coatings, only the vertical burn test is performed known as the UL94 flammability test.

Certification

Coatings that meet the Standard are listed on the UL database and are categorized as conformal coatings, permanent coatings and resist coatings. These products also bear the UL symbol on the product label for easy identification.

MG Chemicals has several UL recognized products:

- Coatings for use on printed writing. See UL File # E203094.

- Plastic Components. See UL File # E334302.

- Metallized Parts—Component. See UL File # E202609.

Understanding The UL94 Vertical Burn Test

Background

Underwriter’s Laboratories (UL) is a global safety certification company that performs testing on products across many industries to determine if they are fit-for-use. It is commonplace to see the UL label on consumer goods throughout the world, including on plastics used for electronics. Specifically, these materials are tested for flame retardancy – the ability to self-extinguish when exposed to fire. Flame retardant materials are becoming a critical component in modern circuitry as designers implement safeguards to ensure that fire will not spread in the case of ignition.

Testing Specifics

This test can be performed on either conformal coatings or plastics used in electronics.

When testing conformal coatings, strips of FR4 laminate (which contain bromine to make the strip itself flame retardant) are used as a substrate. Both sides of the strip are coated to a desired thickness, with most manufactures aiming to achieve flame retardancy over a thickness range (reported by UL as min. and max. coating thickness in microns).

For plastics, the strip itself is fabricated from the material being tested, with thickness ranging between 1.5 to 3.5 mm.

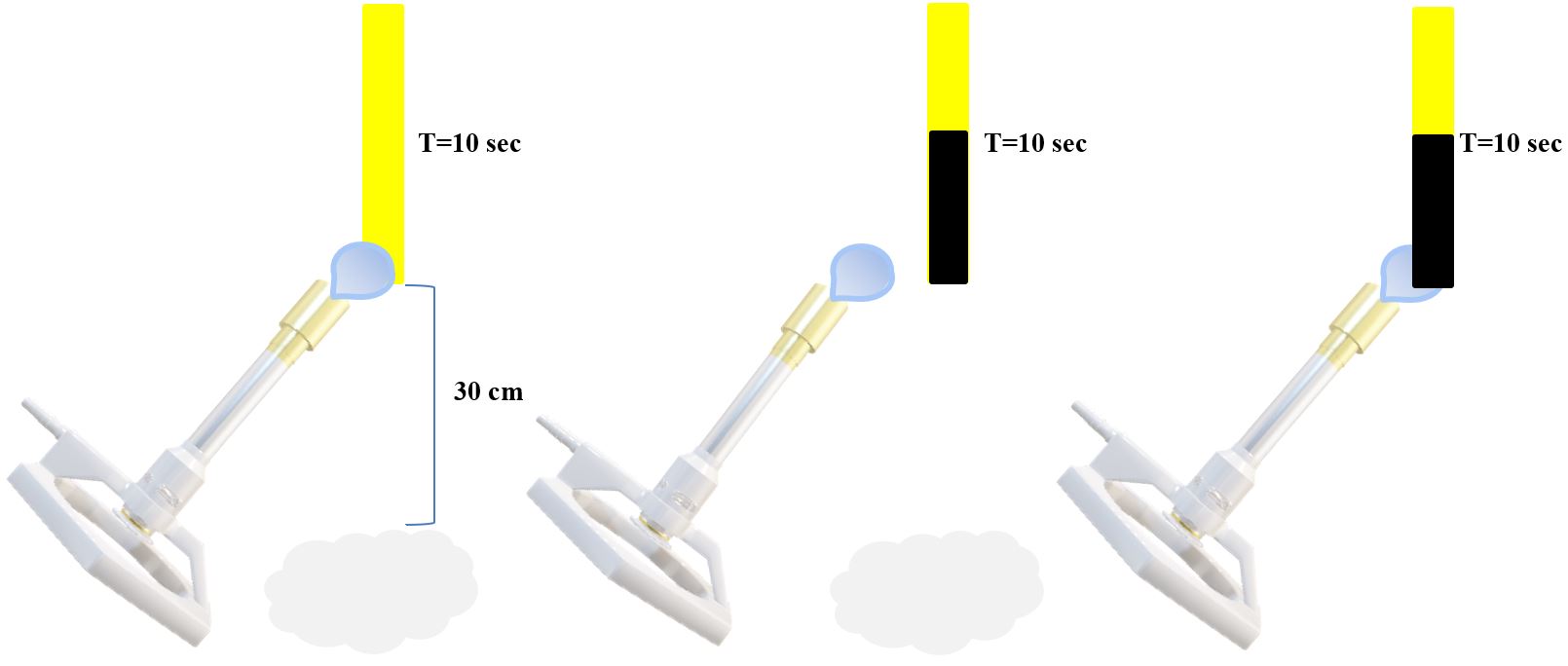

For this test, the substrate is clamped in the vertical position and set on fire using a 20 mm blue flame held at a 45° angle, 10 cm from the bottom end of the test strip. Cotton balls are placed 30 cm below the bottom end of the specimen to check for flaming particles that might drip from the test surface. The test is performed in two stages. First, the flame is held up to the specimen for 10 seconds, removed, and allowed to self-extinguish. The flame is then re-introduced to the specimen for an additional 10 seconds, then removed. Figure 1 (below) illustrates the test setup.

Should the flame reach all the way up to the holding clamp, the specimen is deemed a failure and no designation is awarded. Successful designation of the material depends on the extent of burning after the flame has been removed following the second ignition phase, tested on five prepared samples. Table 1 (below) outlines the criteria required to achieve specific UL94 designations:

| V-0 | V-1 | V-2 | |

| Burning time of sample after flame application (secs) | ≤10 | ≤30 | ≤30 |

| Total burning time for 5 samples (secs) | ≤50 | ≤250 | ≤250 |

| Afterglow time following second ignition (secs) | ≤30 | ≤60 | ≤60 |

| Ignition of cotton balls | No | No | Yes |

| Combustion up to holding clamp | No | No | No |

Certification

Products that pass the standard are listed on the UL database either as coatings or plastics. These products also bear the UL symbol on the product label for easy recognition:![]()