Electrically Conductive Materials

There are several circumstances where circuit board manufacturers require electrically conductive materials. During fabrication, solder wire is required to attach components to the board. MG Chemicals offers several options of solder wire, including leaded, non-leaded, no-clean and water-soluble. Solder paste is available for stencilling and high-precision work, including leaded, non-leaded and low-temperature.

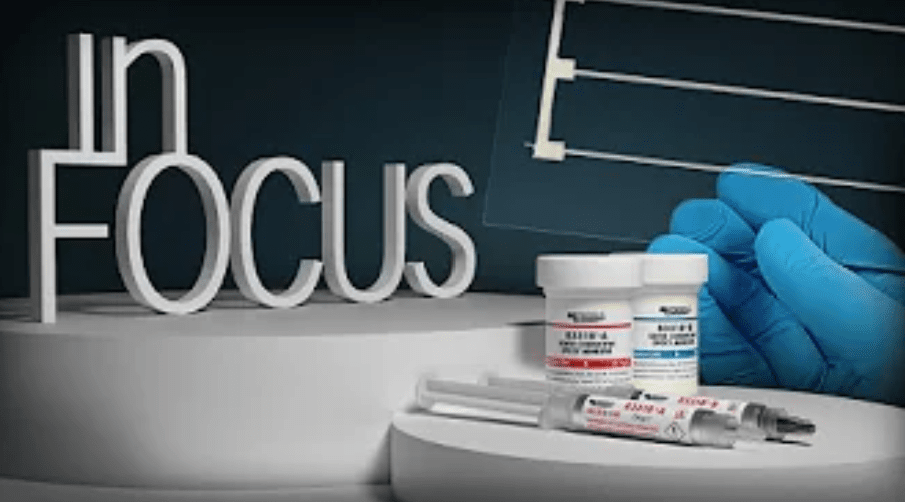

Our electrically conductive epoxy adhesives can be used for cold soldering when components are especially heat-sensitive and cannot go through a typical wave solder process. Our adhesives have many additional uses, including die attach, trace stencilling and EMI shielding. Our products are available in 1 or 2-part systems and have many key features, including short working times, good thermal conductivity and low outgassing.

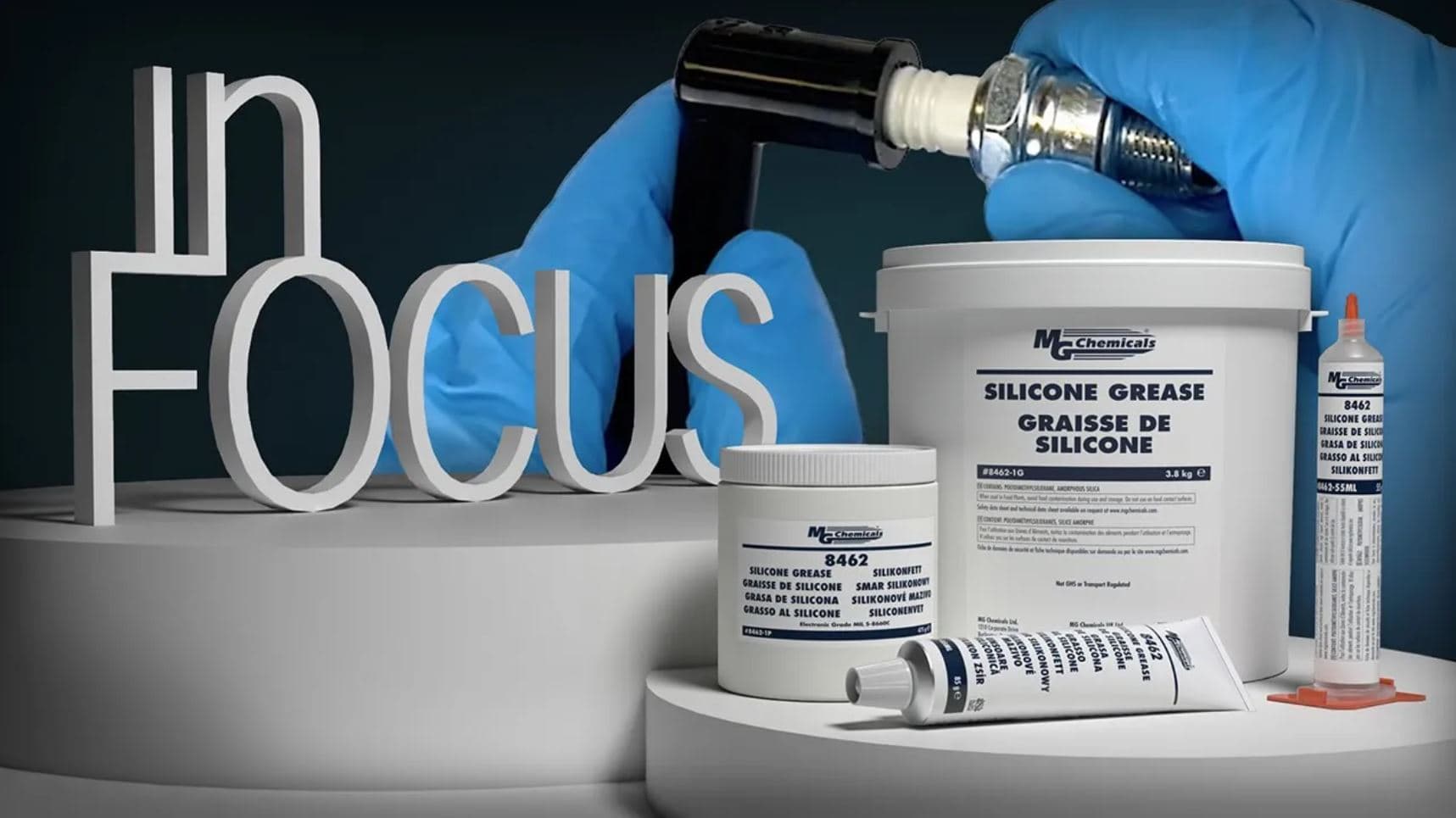

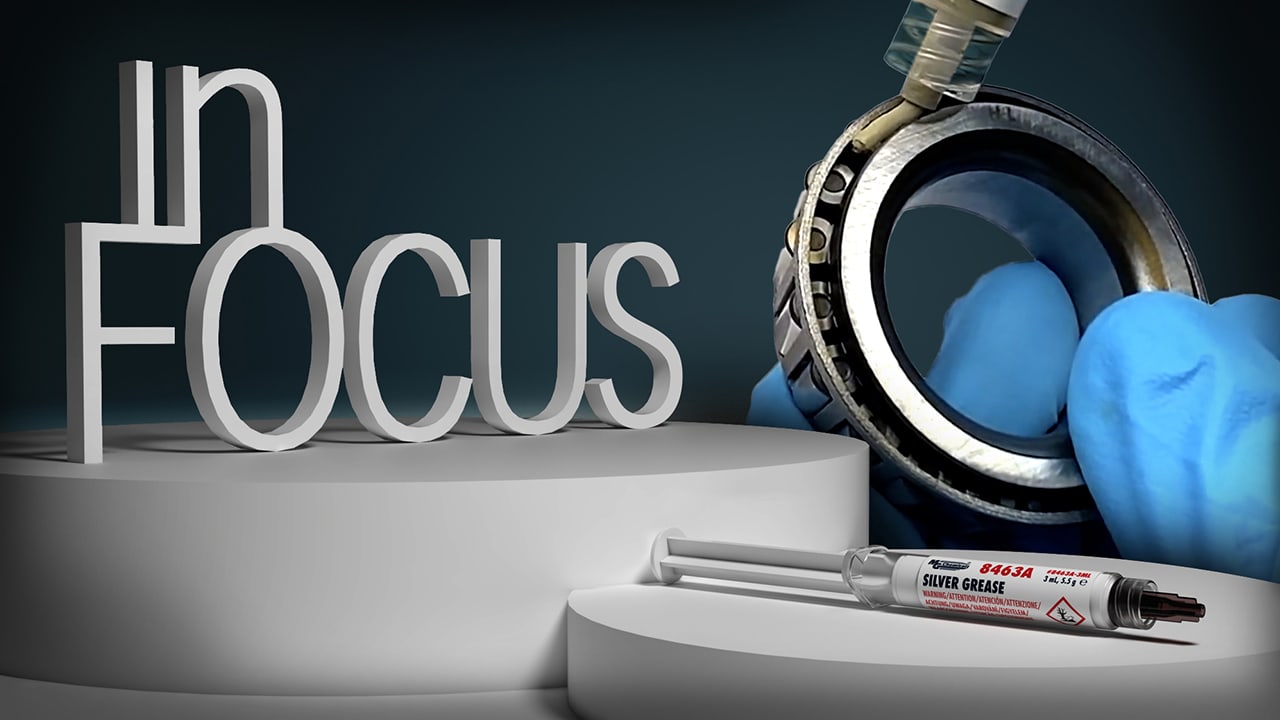

MG offers electrically conductive grease for applications requiring both an electrical conduit between parts and lubrication. Available as carbon-based products or low-cost silver, these products offer many key features such as enhanced conductivity, corrosion protection and lubrication under challenging operating environments.

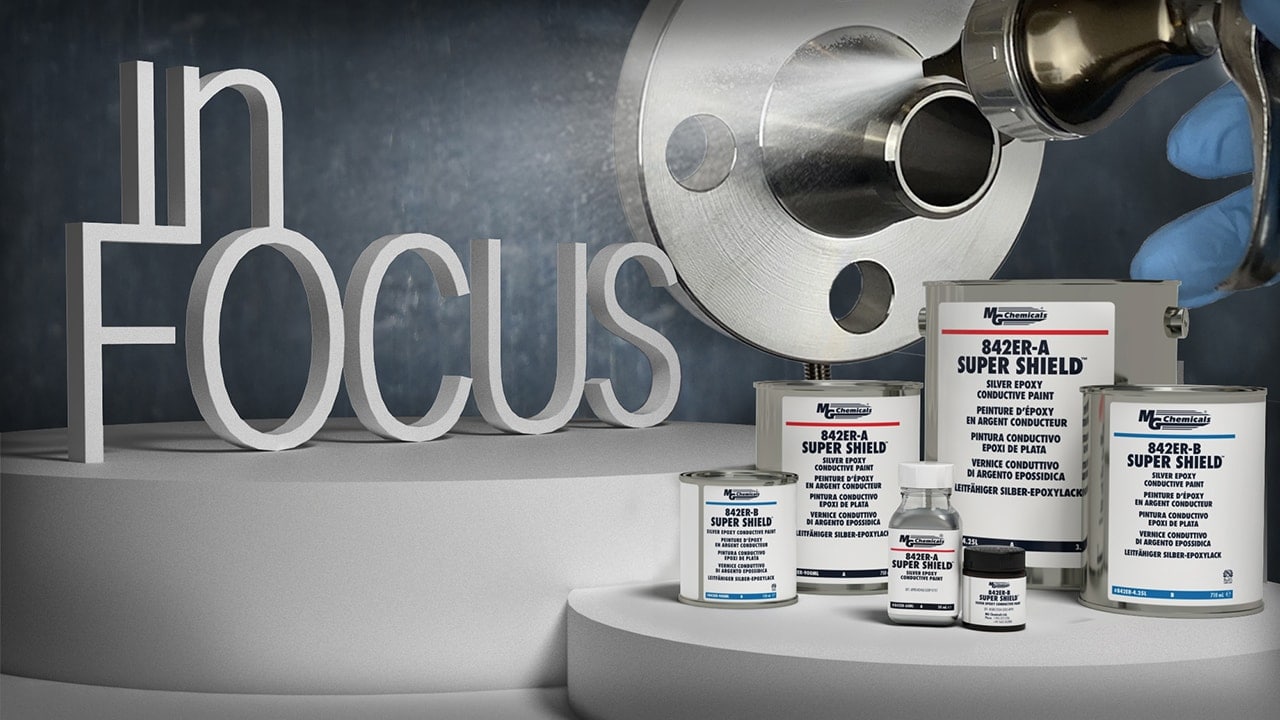

Electrically conductive paint is used primarily to shield circuits from incoming electromagnetic and radio interference (EMI/RFI). These products are applied mainly to the inner edges of plastic housing units to hold circuit boards; however, highly engineered paints with very low dry film thickness build are available for package-level shielding applications. These coatings are available in different chemistries and filler systems to balance key requirements such as adhesion, durability, shielding effectiveness and cost.

Conductive Paints – MG Chemicals offers conductive paints pigmented with branched carbon powder, nickel flake, silver-coated-copper flake, and silver flake.

Electrically Conductive Adhesives – Epoxy systems loaded with high conductivity silver powder. These products are easy to use and a practical alternative when soldering is not feasible.

Electrically Conductive Greases – Loaded with conductive filler, these greases are an easy way to repair damaged electrical connections. Whether contacts have become corroded, or wear and tear prevents a snug fit, our electrical greases fill gaps in irregular surfaces to facilitate smooth, reliable current flow.

Solder Wires – Available in a variety of chemistries, flux types and sizes. Browse our solder wire catalogue to find the right product for your application.

Solder Pastes – Solder pastes offer flexibility over solder wires in terms of application methods, such as automatic dispensing and stenciling, which facilitate higher throughput. Our solder pastes are available in both leaded and non-leaded options.