Conductive Paints

What is Conductive Paint?

Electrically conductive paint is made by mixing an electrically conductive pigment into a non-conductive resin binder. The binder holds the paint together and provides adhesion, while the conductive filler provides the electrical pathway. Electrical charges travel through the conductive fillers, making short jumps through the matrix between particles when necessary. This works best when the fillers are highly concentrated and in the shape of flakes or tubes. Spheres are not optimal for conductivity, but can provide a smooth finish and increased conductivity when used in conjunction with flakes.

Beyond morphology, fillers vary primarily in electrical conductivity, corrosion resistance, and price. MG Chemicals offers conductive paints pigmented with branched carbon powder, nickel flake, silver-coated-copper flake, and silver flake. Carbon is the most cost-effective filler and is fine for RFI shielding and grounding applications. Silver provides the highest conductivity and the greatest shielding effectiveness, especially in high frequency EMI shielding applications. Nickel and Silver-Coated Copper both offer good broad range EMI / RFI shielding. Silver-Coated-Copper excels at higher frequencies, but does not resist corrosion as well as the other pigments.

Binding systems can vary greatly. They impact the conductivity and shielding effectiveness of the coating, but not as much as the choice of filler does. They do play a larger role, however, in determining the adhesion, durability, and chemical resistance of the coating. They also determine how the coating will be applied; properties like working time and number of components are determined by the binder system. MG offers conductive paints formulated with solvent-based-acyclic, water-based, epoxy, and urethane binding systems.

Applications

- EMI / RFI Shielding

- Prototyping and repairing circuits

- ESD protection

- Grounding surfaces

- Galvanic corrosion resistance

- Electroplating plastics

Conductive Acrylic Paints – 1-part coatings that are easy to apply, cure quickly, and provide optimal EMI / RFI shielding to plastic electronic enclosures.

Conductive Epoxy Paints – 2-part coatings that offer superior adhesion, durability, and chemical resistance. They are suitable for use in harsh environments.

Water Based Conductive Shielding Paint – 1-part coatings suitable for use on wood, and excellent for guitars and other instruments. They are also excellent on drywall and suitable for use on walls and other architectural applications.

Package and Board Level Shielding Coatings – Coatings for short-range high-frequency EMI applications. High durability versions are available that resist wave soldering and do not fray when cut.

ESD Safe Coatings – Durable coatings that prevent electrostatic discharge on a wide variety of substrates.

Conductive Spray Paints – Conductive acrylic paints in convenient aerosol packaging.

Conductive Pens – Conductive paints in a convenient pen format, perfect for prototyping, trace repair, and touchup.

Conductive Paint Thinners – Thinners for use in the application of conductive paints

If our Conductive Paints interest you, our Conductive Adhesives might too. To learn about non-conductive coatings applied directly onto circuits to provide protection from almost anything other than EMI / RFI, check out our Conformal Coatings.

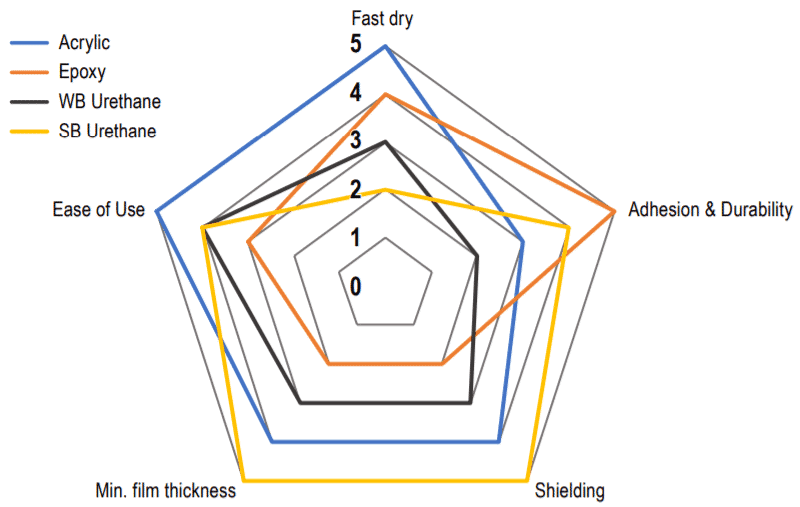

Performance Comparison of Coating Bases

Each coating base comes with its own tradeoffs depending on the application.

Substrate Adhesion

Each polymer system comes with its own adhesion strength depending on the substrate it is applied to.

| Acrylic | Epoxy | Water Based | |

| Acrylonitrile Butadiene Styrene (ABS) | Excellent | Excellent | Excellent |

| Polycarbonate (PC) | Excellent | Excellent | Excellent |

| PolyVinyl Chloride (PVC) | Excellent | Excellent | Excellent |

| Nylon 66 (Polyamide) | Excellent | Excellent | Excellent |

| G-10 Fiberglass Epoxy |

Excellent | Excellent | Excellent |

| Ceramic |

Excellent | Excellent | Excellent |

| Polypropylene (PP) | Poor | Poor | Poor |

| Glass | Poor | Excellent | Poor |

| Metal | Poor | Excellent | Poor |

| Dry Wall | Good | Good | Excellent |

| Wood | Good | Excellent | Excellent |

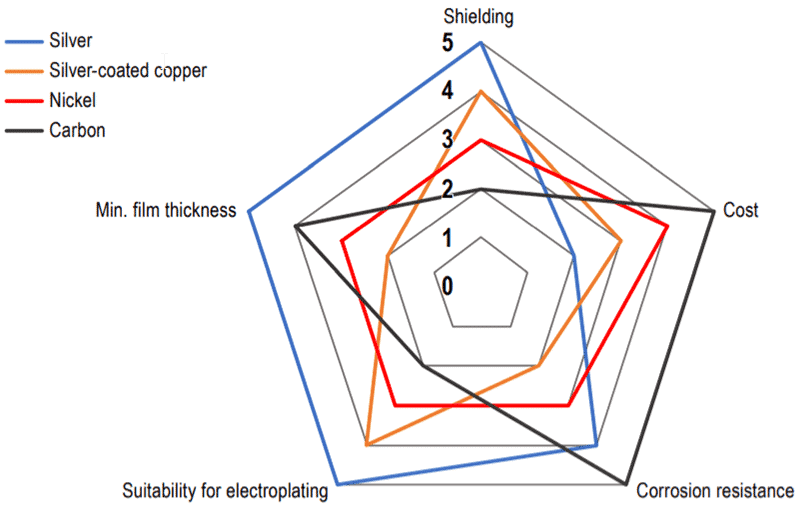

Performance Comparison of Coating Pigments

Each conductive filler comes with its own tradeoffs depending on the application.

Pigment/Resin Systems Combination Product Selection Chart

| Resin System | |||

| Pigment System | Acrylic | Water Based Urethane | Epoxy |

| Carbon | 838AR | N/A | N/A |

| Nickel | 841AR | 841WB | 841ER |

| Silver Coated Copper | 843AR | 843WB | 843ER |

| Silver | 842AR | 842WB | 842ER |