Poured Resin Art

Clear epoxy resin is useful in electronic potting as it allows the user to see components and spot any potential malfunction within the hardware. Clear resin has also found much utility within the DIY and crafting community. Clear epoxy resin for crafts has become a popular commodity for fabricating jewellery, river tables, countertops, and canvas art. Esthetics here is paramount as imperfections such as bubbles ruin the overall quality of the art.

Bubble Free Epoxy Resin

MG Chemicals’ 832WC is a 2-part, optically clear epoxy resin that cures to a tough, rigid finish. To cure the resin, two parts of resin are mixed with 1 part hardener by volume. The components are stirred together for two minutes to ensure complete mixing, producing a lot of air that enters the mixture, appearing as small bubbles dispersed throughout the resin. In this paper, we will compare five techniques for removing ingressed air.

Method

A bulk sample of 100g 832WC was prepared and then evenly decanted into five polycarbonate containers. Colouring dye was added to each sample to represent a different technique used to remove bubbles. The first sample is the control, where no method was used to remove bubbles serving as a way to compare the efficacy of the techniques used in subsequent samples. Table 1 below summarizes the five different approaches employed in this experiment.

| Sample | Colour | Technique |

|---|---|---|

| 1 | Yellow | None |

| 2 | Blue | A blow torch used to heat the surface |

| 3 | Red | A hot air gun used to heat the surface |

| 4 | Green | Placed in a vacuum chamber and pumped until smooth |

| 5 | Purple | Placed in a hot oven after mixing |

Results

In the first sample – the control with no intervention – there are still lots of bubbles embedded within it. These random air pockets ruin its final esthetic. Sample 2, which used the flame, worked very well to remove the air giving the cured sample a nice, smooth appearance. The same can be said for sample 3, which used a heat gun to achieve the same results. Sample 4 used a vacuum chamber which sucked all the ingressed air from the sample to leave a smooth, bubble-free finish, while sample 5, which used a hot oven to cure the sample, also gave a clean, clear finish. Figure 1 is a side-by-side comparison of the five samples tested. These results can also be viewed in our Tech Talk Episode 8 installment.

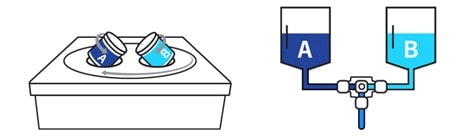

Alternatively, other techniques not featured in this article, such as using a meter-mix system or a dual action revolution and rotating planetary mixer, can be employed to give you a smooth, bubble-free finish. MG Chemicals also offers certain products in a dual cartridge package, allowing for simple dispensing that introduces no air into the mixture.