USA

|

|

|

|

|

|

|

|

|

|

|

|

|

Canada

|

|

|

|

|

|

Europe

|

|

|

|

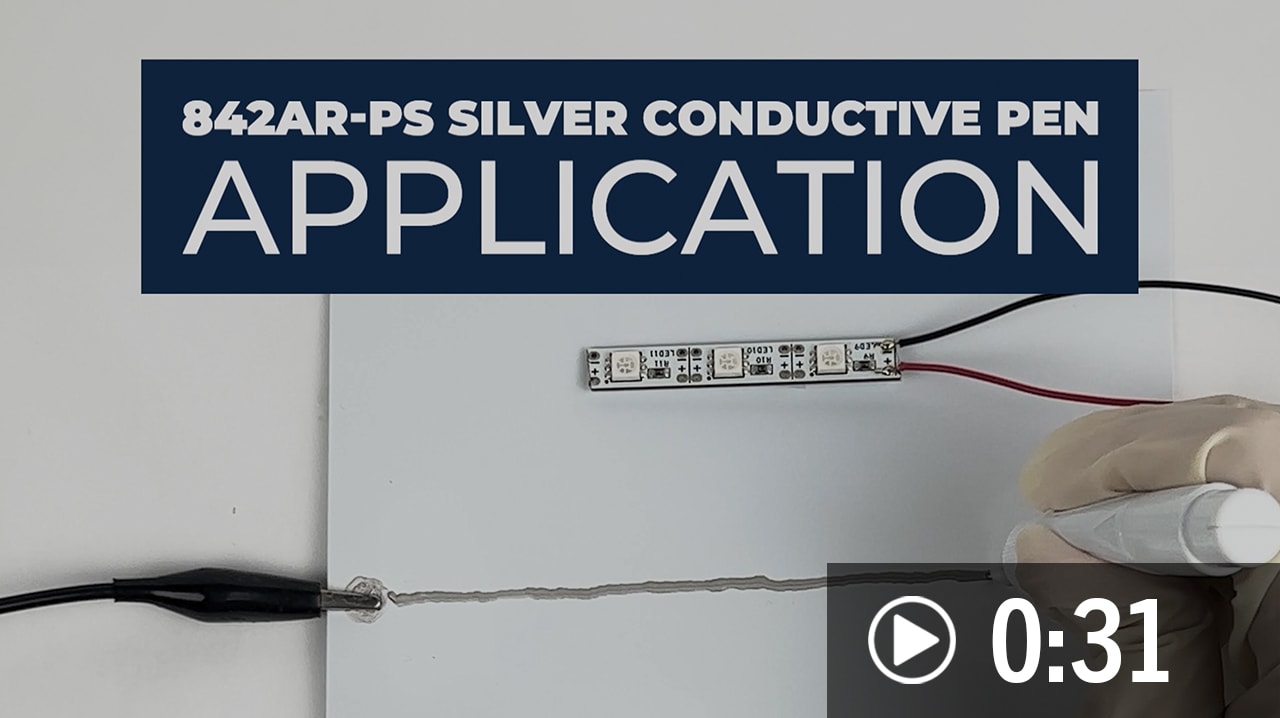

A silver conductive pen that dispenses acrylic lacquer pigmented with highly conductive silver flakes. The cured traces are durable, corrosion resistant, and highly conductive. They adhere well to plastics and most electronics substrates. The valve tip opens when pressed against a surface, and the flow is controlled by squeezing the barrel. The product works best on a smooth, flat, hard surface, but the cured circuits are highly flexible.

This conductive pen can draw electrical circuits for prototyping, hobbies, or maker projects. It can also repair damaged circuits on keyboards, game controllers, remote controls, mixing boards, and PCBs. It can also make small connections in or between circuits, such as jumpers, through-holes, and bridges. As well, it can be used to increase the surface areas of contacts by painting the area around them.

This product is our best conductive pen. For applications where high conductivity is not required, the 838AR-P Carbon Conductive Pen and the 841AR-P Nickel Conductive Pen provide economical alternatives. This product is also available in liquid and aerosol formats.