Epoxy Potting Compounds

Electrically Conductive Grease

Epoxy Potting Compounds

Electrically Conductive Grease

At MG Chemicals, we’re committed to driving innovation and empowering the next generation of scientific pioneers. Our University Project Sponsorship opportunities are tailored to fuel creativity, collaboration, and groundbreaking discoveries within the academic sphere. If you’re a university educator, researcher, or student looking to transcend the boundaries of chemistry and technology, we invite you to explore the endless possibilities with MG Chemicals.

Learn More

Showing 1–12 of 28 results

MG Chemicals has developed an expansive portfolio of conformal coatings to meet the current challenges of circuit board protection. These products are designed specifically to protect circuits from common contaminants like moisture, dust, chemical vapors, fungus, and corrosive gasses, thereby extending product life.

With a wide array of chemistries available, such as acrylic, polyurethane, epoxy, silicone and UV cure, users can find a customized solution that balances protection requirements with processing needs. Our products come in a variety of viscosities ideal for either brush or selective spray application and are certified to industry-leading conformal coating standards like IPC-CC-830C and UL746E. Browse our available products and contact our technical support staff to determine which product is right for you.

Conformal coatings are clear, flexible topcoats that conform to the intricate geometries of PCBs. They are applied over circuit boards to ruggedize them, and thereby extend product life.

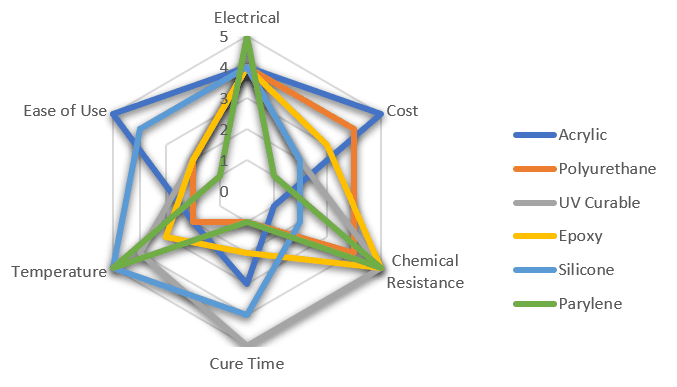

There are currently eight distinct families of conformal coatings, as designated in the IPC-CC-830C Standard. These comprise acrylic, polyurethane, silicone, epoxy, UV curable, parylene, ultra-thin and styrenated block-copolymer types. The table below summarizes the pros and cons associated with each coating type.

| Material | Advantages | Disadvantages |

| Acrylic | Ease of use, low cost | Poor solvent resistance |

| Polyurethane | Abrasion resistance | Long cure times |

| Epoxy | Chemical and scratch resistance | Difficult to use and rework |

| Silicone | High temperature resistance | Poor solvent resistance |

| UV Cure | Very fast cure time | Expensive, high capital cost |

| Parylene | Completely conformal and uniform | Expensive, difficult to apply |

| Ultra-Thin | Fast cure, good hydrophobicity | Less surface protection than other coatings |

| Styrenated Block-copolymer | Superior moisture protection | Poor solvent resistance |

Choosing the right technology will depend principally on considerations like: What (if any) certifications do I require? What are the main environmental concerns I need protection from? And, what are my processing capabilities? Ultimately, proper material selection comes down to knowing all of your requirements. Please contact MG Chemicals technical support if you need any assistance ([email protected]).

Acrylic Conformal Coatings – 1-part acrylic conformal coatings are the most widely used due to their ease-of-use, ease-of-repair, and excellent resistance to moisture.

Available in both liquid and aerosol formats.

Polyurethane Conformal Coatings – 1-part coatings known for their versatility, flexibility, adhesion, and mar resistance. Polyurethane conformal coatings find applicability in more harsh environments particularly where corrosive elements are present.

Available in both liquid and aerosol formats.

Silicone Conformal Coatings – Available as both pure silicone and silicone/acrylic hybrid systems, silicone coatings provide enhanced thermal protection and wider service temperature compared to other chemistries.

Available in both liquid and aerosol formats.

Epoxy Conformal Coatings – Epoxy conformal coatings are ideal materials for PCBs exposed to the harshest conditions. Consider using an epoxy coating when your board will be exposed to corrosive elements, chemical solvents or damage from high impact particles.

Only available in liquid format.

UV Conformal Coatings – When faced with high volume processing demands, UV curable conformal coatings, which cure in seconds, facilitate high throughput without compromising on quality.

Only available in liquid format.

Insulation Coatings – Distinct from conformal coatings due to their enhanced insulation properties, insulation coatings offer a convenient solution when the electrical isolation of high voltage parts such as motor windings and coils is required.

Conformal Coating Sprays – Available for acrylic, polyurethane and silicone/acrylic hybrid products, aerosols offer the benefits of spray application without the need to install expensive pneumatic equipment, making them ideal for low-volume projects.

Conformal Coating Strippers – A powerful combination of solvents that breaks down chemical bonds allowing you to strip away unwanted coatings or adhesives. Also available in a gel for more selective removal.

Conformal Coating Thinners – Solvents for thinning out conformal coatings for better application. Consult the conformal coating technical data sheet for recommended thinners.

Overcoat Pens – Perfect for making spot repairs on PCBs, overcoat pens contain 419D acrylic conformal coating in multiple colors for minor touch ups.

Conformal coatings are used to help extend the life of circuit boards by providing a layer of protection against common environmental elements, such as moisture, dust, dirt, and fungus. These coatings have excellent dielectric properties that help prevent flashover, which allows traces to be placed closer together and thereby facilitates the design of smaller, more powerful electronics components.

There are two main standards for conformal coatings: UL746E and IPC-CC-830. The UL746E Conformal Coating Standard comprises a series of dielectric tests that measure the coating’s insulation properties following environmental stress, as well as its flame retardancy. The IPC-CC-830 standard was created by the Institute for Printed Circuits (IPC) to replace the MIL-I-46058C Standard, which was declared inactive in 1998. This standard test the coating’s durability against thermal shock, hydrolytic aging, moisture saturation, fungal resistance and flame retardancy.

We have provided more specific details concerning both the UL746E and IPC-CC-830 Standards in these two articles.

Defects in conformal coatings are the same as those encountered when applying any paint. By learning how to apply conformal coating, you can streamline turnaround and avoid issues on the paint line. Below is a summary of the most common coating defects, and how they can be alleviated.

|

De-Wetting – De-wetting occurs when a coating fails to spread (or wet) over parts of the substrate, and subsequently floods adjacent areas. This happens when common residues such as flux, grease, oil or cutting fluid remain on the surface, impeding the natural flow of the coating and preventing it from spreading out and levelling. The solution is to clean the substrate thoroughly until no contaminants remain. |

|

Orange Peel – As the name implies, “orange peel” results in a bumpy, contoured surface finish that resembles orange peel. This issue stems from the spray technique – namely, setting the spray pressure too low, which provides insufficient atomization, or from using the wrong thinner. Avoid “orange peel” by using the spray settings and thinners recommended in the product’s Technical Data Sheet (TDS). |

|

Bubbled Surface – “Bubbled surface” is caused by three things: 1) Applying the coating with too much pressure, which ingresses air into the liquid coating. 2) Letting the coat dry too quickly, which allows insufficient time for the film to level and deaerate. 3) Applying the coating too thickly, which traps solvent vapors. To prevent “bubbled surfaces” avoid heavy coats; instead build film thickness by laminating successive thin layers. Refer to MG Chemicals’ Technical Data Sheets for recommended spray settings and dry time-to-handle for each conformal coating product. |

|

Fisheyes – Fisheyes look like small circular lumps with dimples in their centers. They are usually caused by contamination from oil and debris in spray equipment lines. To resolve this issue, simply install a filter that ensures only clean air will be used to spray the coating. |

|

Overspray – Conformal coating overspray occurs when coating is accidentally applied to the wrong area. This can happen when the natural mobility of low-viscosity fluids lets them spread to inappropriate areas (known as “wicking” or capillary action), through operator error, or by uncontrolled wetting of aerosolized liquid coatings. The remedy: do not try to avoid overspray, anticipate it and take preventative measures – namely masking. Masking involves applying a protective material, such as painter’s tape or peelable latex, to areas where the coating is not wanted. Once the coating has been applied, the masking should be removed quickly, before it dries, to prevent unwanted removal of cured coating. |

The application of a conformal coating requires several subsequent processes to achieve both proper coverage and an aesthetic finish.

PCB Cleaning – To avoid coating defects like de-wetting, and achieve a smooth, homogeneous film, substrates must be cleaned vigorously to remove unwanted contaminants such as flux, grease and oil. MG Chemicals has an expansive portfolio of cleaning products to help ensure that surfaces are clean and ready for conformal coating.

Masking – To prevent conformal coating overspray, where coating is deposited in unwanted areas, substrates must be masked in keep-out areas. Masking is achieved either by using simple materials like painter’s tape, or a peelable solder mask such as MG’s 862. It is important to remove the masking soon after application and before the coating has cured, to avoid peeling away any of the coating.

Applying Conformal Coatings – Various coating techniques can be used, depending on the volume of parts to coat, and the capabilities of your organization.

For small repairs and low-volume jobs, brushing is an ideal technique as it requires no preparation. It is very precise and requires no expertise. Dipping is also ideal for low-volume work, reliable coating penetration under components and generally fast processing, but it may require intensive masking and can be messy.

For high-volume projects, spray technique becomes important, and is ideal when rapid turnaround, enhanced edge-tip coverage and better film uniformity are required.

Spraying can be accomplished using a simple pneumatic spray gun in a dedicated fume booth. However, this technique requires some expertise and may require masking The spray process can be streamlined by using automated equipment of the sort made by PVA, Nordson Asymtek and Specialty Coating Systems. These systems provide speed and precision to maximize throughput and minimize rework.

Cure – There are three types of conformal coatings classified by their curing mechanisms: thermoplastic, thermoset and UV-curable. Thermoplastic materials include acrylics and silicone/acrylic hybrid coatings. They cure by physical drying as solvent simply evaporates, leaving the coating film. These coatings can be cured either under ambient conditions or by using heat. Thermoplastics are materials that undergo a chemical reaction as part of their curing mechanism. Like thermoplastics, they can typically be cured under ambient conditions. However, to achieve optimum properties and full cure, these coatings require elevated temperatures. UV-curable materials are acrylates and methacrylates that cure when exposed to certain wavelengths of UV light.

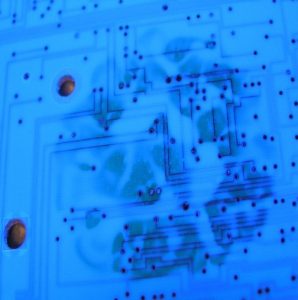

Quality Control – The main consideration when inspecting conformal coatings is coverage. This can be done quickly and easily using a black lamp. Simply place the coated board under a black lamp and check for areas which fluoresce blue.

Measuring Conformal Coating Thickness – Typical dry film thicknesses of conformal coatings range from 1 – 5 mils (25.4 – 127μm) and can be verified using the following techniques:

Micrometer – A simple non-destructive method is to measure points along the uncoated substrate with calibrated micrometers then re-measures these points afterwards, with the difference being the coating thickness.

Positector – A less cumbersome, non-destructive technique employs a digital coating thickness gauge which measures changes in either magnetic or electric fields to determine film thickness. While this technique is much quicker and easier, it is limited to use on conductive substrates, and therefore cannot measure coating thicknesses over solder mask or other insulated components.

Micro-Section Analysis – The easiest non-destructive tool to use when measuring coating thickness is a wet film gauge with a black lamp. However, this method can only be applied with high solids systems, such as UV coatings. Finally, for highly accurate coating thickness measurements, cross-section analysis can be applied in which a section of the coated substrate is cut out and mounted in a plastic mold. The cross section is then polished and analyzed under a powerful microscope to measure the coating thickness at different points. While this technique provides the most accurate measurements, it requires much time and costly equipment, and destroys the sample.

Rework / Repair – Occasionally, repairs are required to touch up areas where coating has become damaged, delaminated, or otherwise removed from the substrate. This typically occurs over a very small area that requires precise application. Therefore, these repairs are typically applied by brush to localize and confine the reapplied coating to a small area.

Choosing the right conformal coating depends on your material needs – namely, which certifications (IPC or UL?) are required, what environmental conditions the coating must withstand, and what your processing capabilities are. Thus, conformal coatings should not be ranked best-to-worst, but rather upon best fit. For example, an indoor circuit board does not require the extreme protection afforded by an epoxy, just a simple acrylic conformal coating that protects against dust and electrical surges. Conversely, a PCB mounted

under the hood of a car requires the enhanced protection of epoxy or UV cure materials that can deal with fuel vapors, road salts and frequent shocks. When choosing a coating system, each conformal coating technology must be evaluated on both its strengths and shortcomings, weighed against your specific needs.

Acrylics – Acrylics are excellent materials for mild environments where the main concerns are intermittent exposure to humidity, salt spray, dust, and fungus. Its strengths are low cost, ease-of-use and rework. Its disadvantage is poor chemical resistance.

Polyurethane – Polyurethanes provide all the protection of acrylics plus some resistance to chemical solvents, feature excellent abrasion resistance and maintain strong adhesion at low temperatures. Their downside is their relatively long cure time, which makes them less than ideal for high volume applications.

Epoxy – Epoxies provide superior protection compared with acrylic, polyurethane and silicone. They protect against common contaminants like moisture, but also against harsh chemicals and abrasion, and help secure solder joints against shocks. Application can be relatively cumbersome, with a long cure time, so their use is generally limited to applications that require enhanced protection.

Silicone – Silicones are prized principally for their high temperature resistance and softness. Compared to most other conformal coating types, silicones have an exceptionally low modulus, which makes them ideal for coating delicate surface mount devices or for applications that involve harsh thermal cycling. Silicone coatings are not used when protection from oils and other solvents is required, and can sometimes be cost-prohibitive when compared to other products.

UV Cure – UV cure materials boast unrivalled cure speeds. Other chemistries take hours to cure, but UV materials can be cured in seconds, which helps to ensure high throughput, making them ideal for large-volume projects. However, to realize their full benefit, substantial capital expenditure is required, including automated spray equipment, radiometers and curing lamps/conveyor systems. So before opting for UV, a thorough cost benefit analysis should be done.

Parylene – Parylene is distinct from every other conformal coating technology in that it is a powder that is applied to PCBs through a process known as chemical vapor deposition. This process is extremely cumbersome and requires highly specialized equipment. However, the cured coating offers unmatched electrical insulation, overall coverage and temperature resistance. Parylene is used exclusively when a completely homogeneous film is a must.

| Material | Typical Dry Time Range |

| Acrylics | 3 – 30 minutes |

| Polyurethanes | 15 – 60 minutes |

| Silicones | 2 -10 minutes |

| Epoxy | 4 -12 hours |

| UV Cure | Seconds after UV exposure |

| Parylene | N/A |

| Ultra-Thin | Under 2 minutes |

| Styrenated Block co-polymer | 5 – 10 minutes |

Typical film thicknesses of conformal coatings range from 1 – 5 mils (25.4 – 127μm) and can be verified using the following techniques:

| Material | Method |

| Acrylics | Easily removed using common solvents like or esters. |

| Polyurethanes | Can be removed using 8309 or 8310A stripper. Takes 5-10 minutes. |

| Silicones | Easily removed using common solvents like acetone or esters. |

| Epoxy | Remove using 8309 or 8310A stripper. May take up to 2 hours. |

| UV Cure | Remove using 8309 or 8310A stripper. May take several hours. |

| Parylene | Must be removed with micro-abrasion. Very difficult. |

| Ultra-Thin | Easily removed using common solvents like Ketones |

| Styrenated Block co-polymer | Easily removed using common solvents like Ketones |